Mold Correction Service

We realize the world's highest level of smooth correction shape by new algorithm*.

* To the representative (Ph.D)'s certain knowledge.

Service Overview

Mold Correction and Its Usefulness

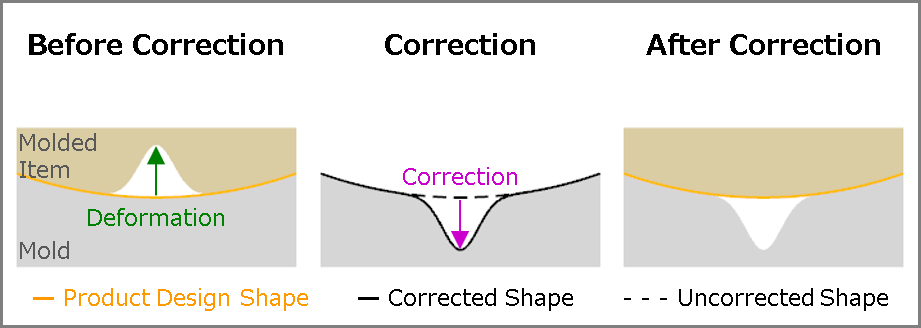

Mold correction is the design act of modifying the design shape of molding surfaces in order that the shape of molded items that shrink and deform during cooling approaches the design shape of molded products (see Fig. 1). When there is a technology that can accurately perform this action, the feasibility of mass production of molded products can be improved since it becomes possible to manufacture high-quality molded items that meet shape specifications even under low-cost molding conditions that are disadvantageous for molded items to meet the specifications.

Conventional Mold Correction Technologies and Its Problem

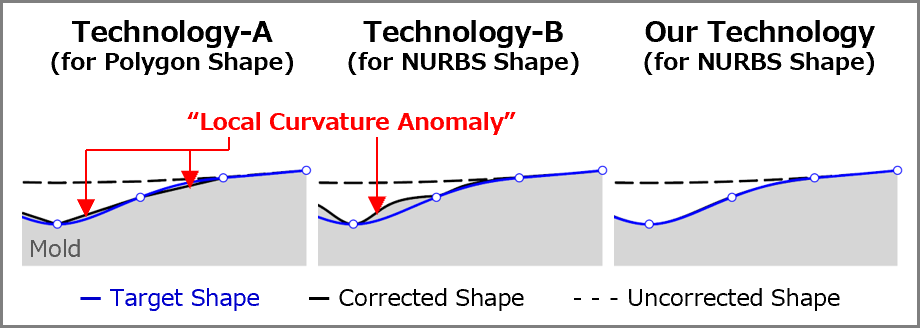

Mold correction technologies can be roughly divided into a mold correction technology that can be applied to the molding surface design shape that is represented by analytical functions (see a 1992 treatise), a mold correction technology that can be applied to the design shape that is represented by polygons (see a 2015 treatise), and a mold correction technology that can be applied to the design shape that is represented by NURBS (other company's product). The third technology ("NURBS Representation Type" technology) is the most technically difficult, so it has the highest degree of freedom in applicable shapes and is the most convenient in post-processes. However, as far as the representative knows, existing mold correction technologies have a troublesome property of causing local unintentional curvatures to the corrected shape (causing "Local Curvature Anomaly") (see Fig. 2 left & middle). It is almost impossible to remove this "Local Curvature Anomaly" in the subsequent process.

Our Mold Correction Technology and Its Usefulness

Our "NURBS Representation Type" mold correction technology does not cause "Local Curvature Anomaly" unlike existing mold correction technologies (see Fig. 2 right). This technology can greatly improve the feasibility of mass production of molded products whose surface shape has a strong influence on performance.

Service Content

Based on shape evaluation data of a molded item (= data showing the deformation amount of a molded item from the design shape), we correct the 3D-CAD model shape of a molding surface using our mold correction technology (= a numerical calculation program)*.

* Format of CAD data provided from customers (provided to customers): STEP [AP203 or AP214] (STEP [AP203])Service Fee

We provide the optimal mold correction service for the output data of the customer's 3D shape measuring machine (contact). We offer customized mold correction services for customers at 50,000 yen (excluding tax) to 80,000 yen (excluding tax).

Service Quality

As an example, we will introduce the quality of mold correction service for grid-shaped output data (Correction error of 1 μm or less for three types of shapes with a correction amount of 500 μm. Click here for details).

Click here for how to use the service